Machine Screw

Machine Screw

Machine screws are the first parallel threaded drive screw used in ancient clocks and firearms. In the early 1900’s, it was the volume, cheap, low-grade screw and the king of fasteners. There have been many changes to the machine screw in the last 100 years; the threads are rolled and not cut unless the screws are very small or quantities are low volume and non prefered. Screw heads and drives are cold forged again apart from micro-screws.

Head and Drive Types

.

Links: Head types Drive types

.

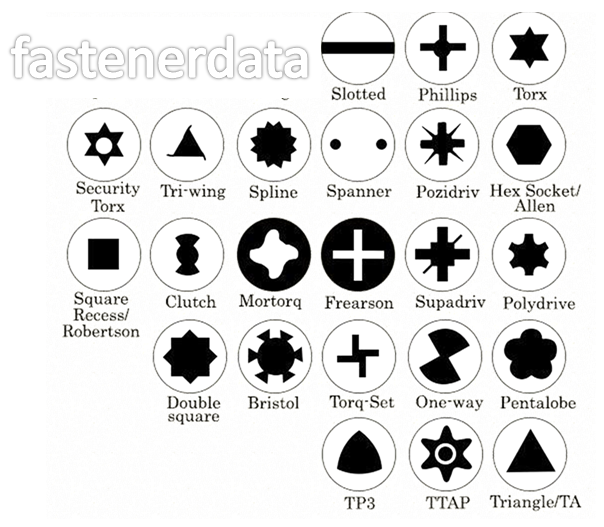

Machine screws are available in a wide choice of driver, and head types, the most popular heads are Pan and Countersunk though a large range of head types are available. These include slotted, Phillips, Pozi, hexagon socket for use with a hexagon wrench, Torx six-pointed star, square-drive socket head and security heads, which are easily assembled but difficult to remove.

Machine screw materials

Machine screws are primarily produced in low tensile steel but are also available in brass, aluminium and stainless steel.

Machine Screw applications

Machine screws are used to fasten components to machines, mechanical tools, and have many functions in phones, electrical appliances, electronic devices and vehicles.

Screw Threads

Machine screws are available with the full range of Metric coarse threads, Unified course, Number and fine threads and British Whitworth, BSF and BA threads. Machine screws are used in tapped holes, thin sheet thread pre-formed or cut holes or with nuts on the opposite side. Small diameter and micro-machine screws are generally cut threads with a slotted drive.

Uniform Threads

Uniform threads maintain the same diameter throughout the entire length of the threaded section of the fastener. Where with tapered threaded screws that have a pointed end such as on wood screws and tapping screws, which are intended to cut their own thread into the softer material.

Machine Screws vs Bolts

Machine screws are slightly smaller than bolts; machine screws also tend to be designated as such if the first tightening of the fastened joint is accomplished by turning the head of the screw. With a bolt, the primary tightening procedure is typically performed by rotating the nut, holding the bolt through a hole. Machine screws are low tensile strength where bolts are medium to high tensile. Machine screws do hot have washer faces.