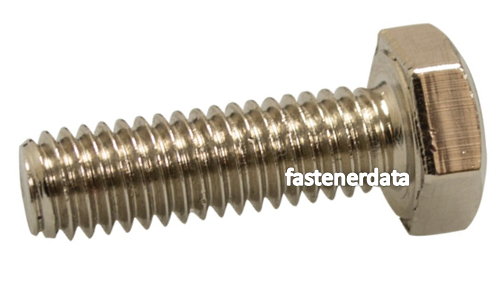

Tin Plated Screws

Fasteners Tin Plated

Fasteners Nuts and bolts of steel and copper can be electro-tin plated. Tin plating is a coating process which involves the coating of metal objects with a thin layer of tin. Tin plating increases the performance and durability of objects is it added to and improves corrosion resistance. Tin creates suitable properties for soldering due to the oxidation protection that tin-plating provides; exposure to air is less likely to tarnish the surfaces of tin plated fasteners.

Tin Plated Fastener user Industries

The leading users of tin plating are electronics, mechatronics, hardware, fasteners, food equipment and solar panels. Typical products examples, electrical terminals and screws, circuit breakers and screws. Screws, nuts and bolts used on marine hardware in naval vessels, fasteners in food manufacturing and home cookware. The conductive properties of tin ensure that it is used for fasteners, bolts nuts and screws; in the electrical and electro-mechanical industries. Tin plated fastener assemblies are widely implemented in the food packaging trade thanks to its non-toxic and corrosion resistant properties.

Benefits of Tin Plating

- Tin has many strengths making it a desirable choice due to its corrosion protection:

- Decent contact resistance and excellent solderability.

- The potential for mirror-like objects for aesthetics.

- Flexibility to use matte tin plating to achieve a dull finish, or bright tin plating when a shinier finish is required

- No known toxicity to life on Earth.

- Tin plating is the lowest cost choice as compared to its rivals up the food chain such as silver and gold plating.

Fastener Electroplated Tin Drawbacks

- Tin's primary weaknesses are its low temperature operating window of less than 450° F

- Intermetallic phenomena are known as tin whisker and dendritic crystal growths, or dendrites, both cause severe damage to electronics by bridging and creating shorts in the electronics in which they are assembled. There is no understood and agreed upon cause of the tin whisker type while dendrites migrate due to electromagnetic reactions of tin ions.

- Environmental that refer to sulfur-bearing environments that cause tin to tarnish.

- Fretting, which means surface to surface corrosion.