Charles Richards

Charles Richards HISTORY of the: Nail Rivet Threads Drives Fasteners Before-1800 Fasteners after 1800

Charles Richards early years

Charles Richards was born in Wednesbury in 1838, after serving an apprenticeship with a local firm of nut and bolt makers he later started his own business. In 1870 he joined forces with William Butler and started making nuts and bolts at Lion Works in Foster Street. They employed around 40 people, mainly in the production of carriage nuts and bolts, which were supplied to railway carriage companies and the leading manufacturers of horse-drawn vehicles; by 1881 the company employed 130 people.

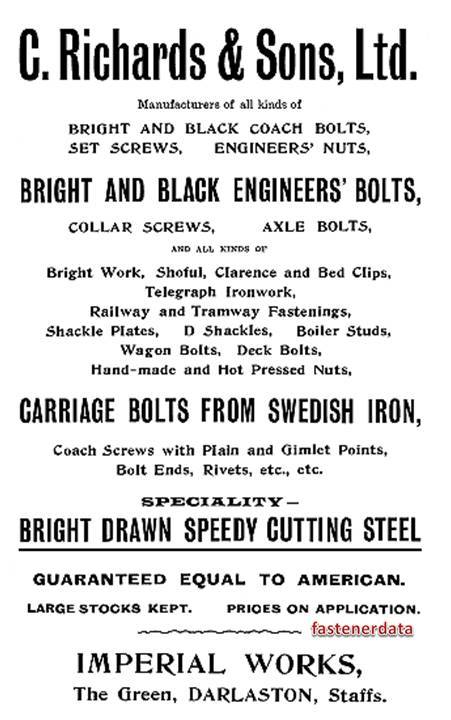

After several years William Butler left the company and Charles Richards went into partnership with Mr Wynn. The firm became known as Richards and Wynn and produced a much wider range of products including bright and black engineer's bolts, coach bolts, nuts and set screws, collar screws, axle bolts, bed clips, boiler studs, shackle plates, "D" shackles, carriage bolts, deck bolts, handmade hot pressed nuts, bolt ends and rivets, and telegraph ironwork.

The bolts and nuts were originally forged with the treadle foot-operated hammer ‘Oliver’, invented in the middle ages, and adapted for bolt and nut making in the early nineteenth century. The larger nuts and bolts were first forged under a steam hammer, before being taken to the Oliver operators to be hand dressed.

Due to a huge demand for the company’s products, Oak Works and Phoenix Works were purchased and by 1881 the company employed 130 people. Within a few years, Mr Wynn retired and four of Charles Richards' sons joined the company making it very much a family concern. They were Silas and Arthur who became responsible for the management of the works, Charles, who looked after the commercial side, and Samuel, who looked after outside sales. They worked hard, and the business prospered, soon outgrowing the three factories.

Charles Richards and Co advised the market that they produced fasteners using only the best materials in steel and iron including the finest brands of Swedish iron.

Charles Richards produced black and bright coach bolts and nuts, set screws, bright and black engineers’ bolts from one-eighth to four inches diameter; also carriage bolts from Swedish iron. By 1911

Charles Richards were drawing their own bright bar and buying thousands of tons of black bars from America, the world’s only supplier.

Machine technology continued to improve, and new machines were acquired to increase production, including National bolt maker cold heading machines, and automatic screwing and pointing machines and Nut cold formers. A new heat treatment plant was installed using the latest type of electric furnaces for hardening and tempering, and the facilities in the test house and laboratory were improved.

Screw spikes had long been a successful product; in 1932 the company received an order from China for five hundred tons of screw spikes.

The company kept an eye on potential global markets and produced fastenings to suit. By the late 1950s, the oil industry had greatly expanded, and so specialised fastenings were produced, which were used throughout the industry.

The home market was not forgotten. In the 1950s the company had agencies in every part of the country, and Charles Richards & Sons became one of the largest private bolt and nut makers in the world. The company became one of the largest employers in the area.

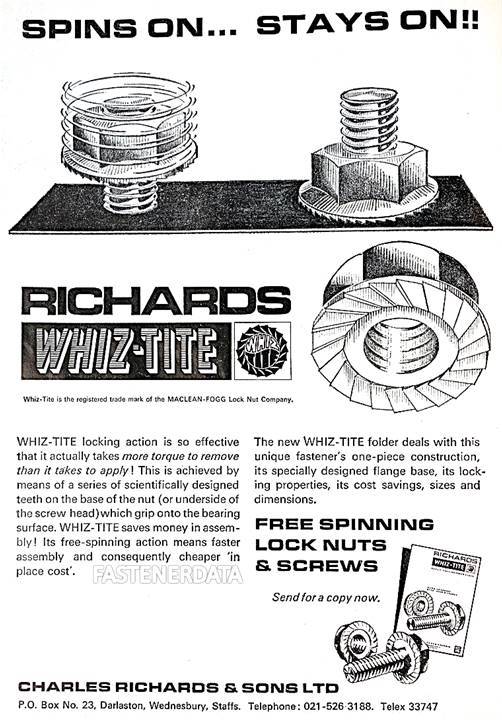

In the 1960s the main products were black, bright, and high tensile bolts and nuts, high strength torque bolts for use in the construction industry, and repetition parts including fish-bolts, screw spikes, rail clips and parts for rail track and telegraph ironwork.

The future looked bright until the beginning of the 1980s; recessions and imported cheaper fasteners forced Charles Richards' son Peter together with John Richards Grant to sell the business to a South African company in June 1980.

Following the takeover and factory closure, the order book and assets were sold to Armstrong Equipment Ltd. The new company Armstrong fasteners had already acquired GSF and later acquired GKN Atlas bolt in 1982.

Caparo acquired Armstrong in 1989; following Caparo global financial problems in 2015, the receivers closed the Caparo fastener division and sold the fastener manufacturing machinery.