Fastener Laboratory Testing

Specialist testing companies offering testing services to fastener companies supplying the Aircraft, Oil, Gas, Petrochemical, Power Generation, Rail and Motorsport industries. They will be able to offer reliable and fully accredited services being UKAS accredited, to enable them to perform quality control, testing, failure investigation, and expert witness services.

Fastener Non-Destructive Testing

PCN (Personnel Certification in Non-Destructive Testing) to British/European Scheme based on BS EN ISO 9712.

Testing includes:

- Ultrasonics

- Dye penetrant inspection

- Magnetic particle

- Radiographic interpretation

- Radiography

Fastener Chemical analysis

- Ferrous

- Non-ferrous metals

- Alloys

Corrosion Testing on Fastener finishes

- Painted finishes

- Plated finishes

- Salt spray

- Humidity testing Thickness of coating

- Adhesion tests

Mechanical Testing of Fasteners

- Tensile tests at ambient and elevated temperatures.

- Impacts at ambient and sub-zero temperatures.

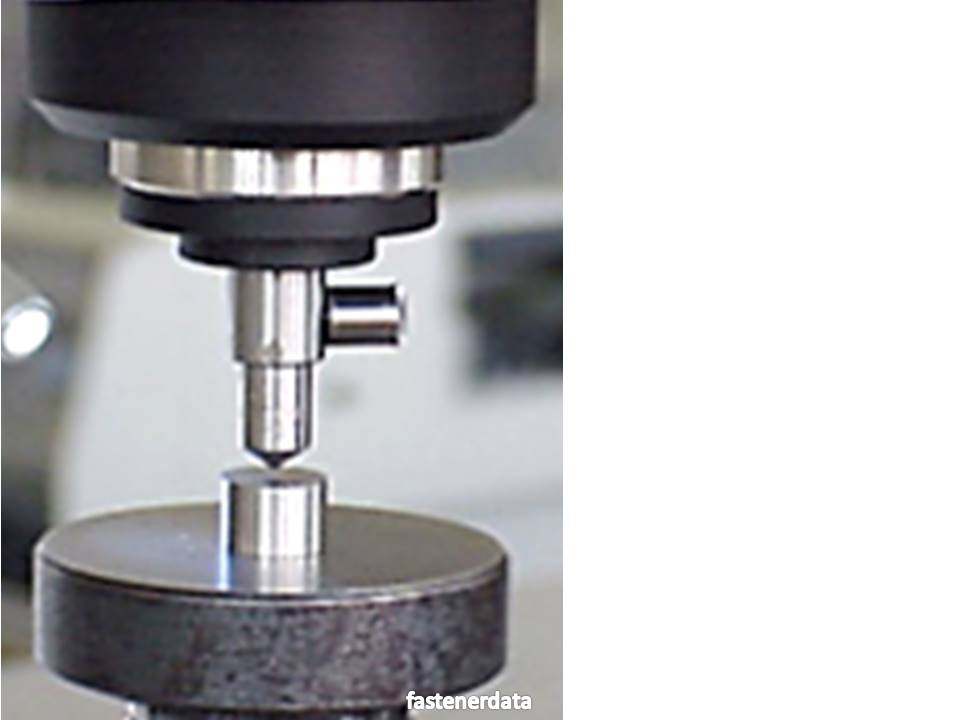

- Hardness testing

- Bend testing

Fastener Microstructural evaluation

- Heat treatment effectiveness

- Case hardness depth

- Grain size

- Coating thickness

Inspection companies will have laboratories that are approved to ISO 17025, fully equipped to meet market demands for metallurgical testing; metallography including failure investigations failure analysis and manufacturing investigations.

Non-Destructive Testing

Chemical analysis

Corrosion Testing on Coatings

Mechanical Testing