Fastener Processes

Fastener Processes

Fastener processes are events following electroplating or coating, most electroplated finishes are followed by a chromate passivation coating that can serve two purposes. The first is to enhance the protection of the electroplating, the second is to change the visual appearance by adding a colour or making the finish look aesthetically brighter.

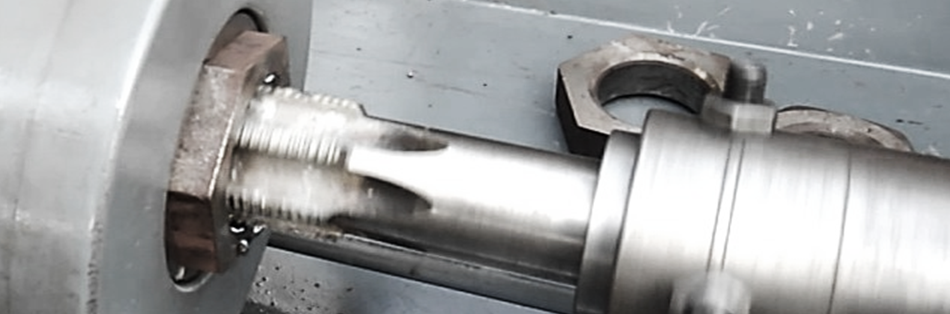

Hot Dip Spun Galvanised fastener products have tight threads after galvanising and need the matting nuts undercut by re-tapping in order to fit the bolts.

Chromate Passivation

Coatings additional corrosion seal and colour, click for more detail

.

.

Retap Nut Threads

Heavey coating requires threads to be chased or retapped, click for more detail

..

.

.

.

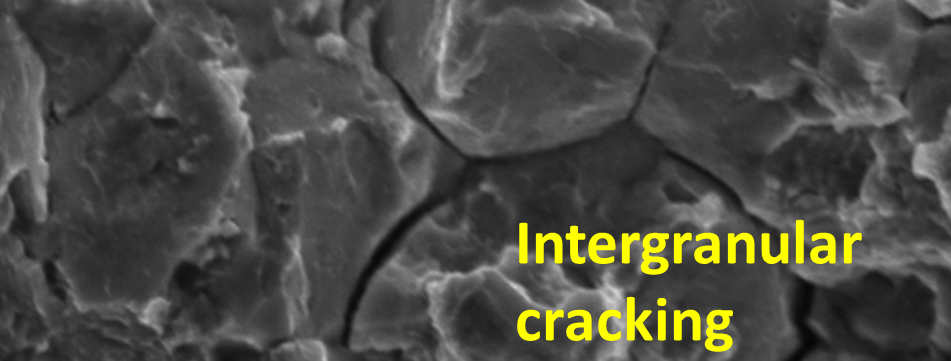

Hydrogen Embrittlement

Dangers of electroplating fasteners higher than class 8.8, click for more detail

...

.

Link to electroplate coatings

.