6 Types Of Spring Plungers

Spring plungers or spring-loaded devices (SLDs) are small narrow devices used to index and position different components. They apply enough pressure after installing that the ball or the nose remains positioned. As their name suggests, spring plungers use spring force to ensure the ball on end remains in position regardless of the amount of pressure applied to them.

Parts Of A Spring Plunger

Spring plungers come in different sizes and types. Each type of spring plunger has its unique function, and so are each of the parts. Most spring plungers have three primary components: the plunger, internal compression spring, and threaded body. The threaded body is the component sheltering the spring, while the plunger sits on the top to apply pressure.

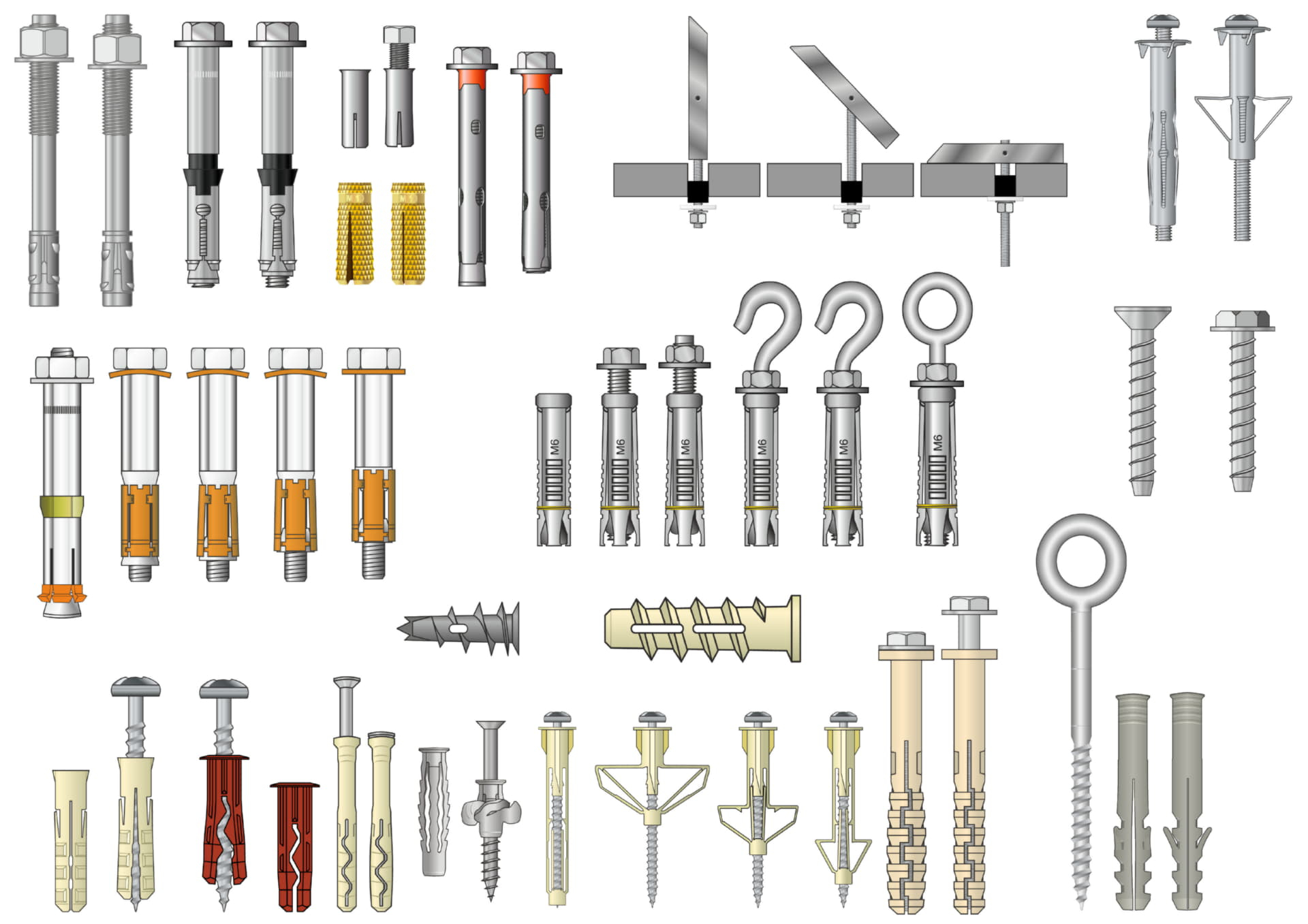

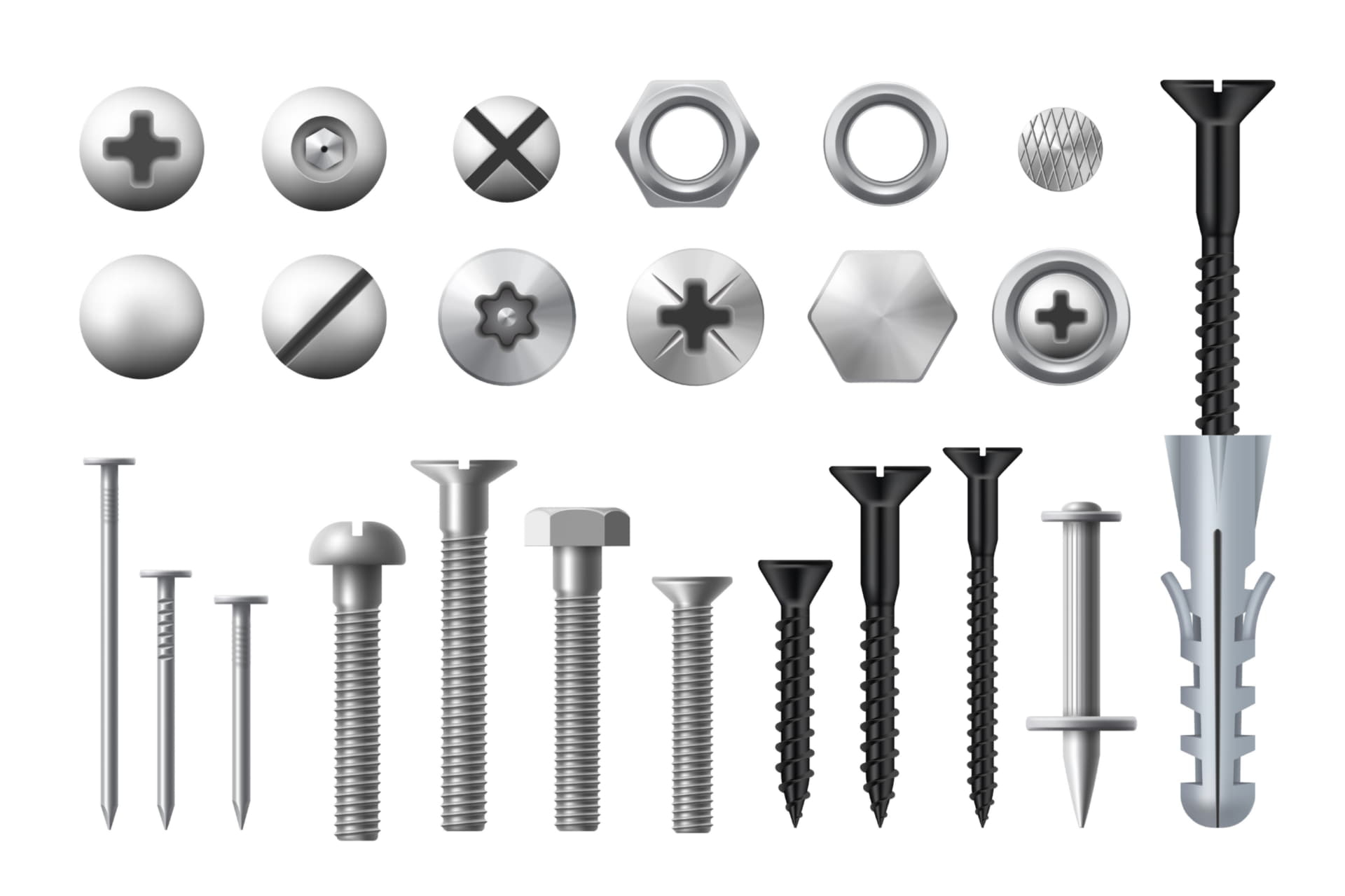

There’s also another essential spring plunger component—a fastener. This ensures that the spring is properly fastened for maximum pressure. This site offers a wide range of fasteners for different spring plungers.

Generally, spring plungers have a simple design, but are extremely useful in manufacturing applications.

Types Of Spring Plungers

As already stated, there are several types of spring plungers. These include:

Pull Pin Spring Plungers

Pull pin spring plungers have an instant release press-fit pull-in structure. The body is threaded into the application, with the ring protruding out to the outer surface. You only need to release the ring to lock the pull-pin spring plunger into a specific position.

Pull pin plungers are suitable for adjusting tubing, latches, tooling, fixtures, gates, and similar equipment. These devices have housing barrels and a plunger assembly. Pull pin spring plungers can be used to retract and engage the plungers for locating, fastening, and quick-change procedures.

Threaded Spring Plungers

Threaded spring plungers are suitable for industrial applications, such as woodwork equipment and machine tools. Threaded spring plungers are made from technopolymer, steel, stainless steel, and thermoplastic. They can be used as shock absorbers or ejectors by applying precise and repeatable spring end forces through rounded noses or balls, particularly in sheet metalworking. These spring plungers come with enclosed springs in threaded housing.

Press Fit Spring Plungers

Press fit spring plungers are suitable when installing equipment on soft materials, such as plastic, aluminium, or wood. Generally referred to as simple and economical spring-loaded devices, these plungers come with an initial load range of 0.01 to 0.50. Among other factors, this load range makes press fit plungers suitable when a threaded hole is impractical or when adjustment isn’t necessary.

Press fit spring plungers apply a heavy spring force, and they mostly come with steel cases. Their diameter ranges from one-eighth of an inch to half an inch.

Indexing Plungers

Indexing plungers are mechanical devices with retractable noses. They’re used to lock items into position in a machine and fixture application to index a set of motions or series of positions. You can settle for either spring actuated or hand operated plungers based on your requirements. You can also go for precision or lock and clamp indexing plungers, or even indexing plungers without a knob.

It’s vital to note that there’s a difference in how each indexing plunger functions. For instance, an indexing plunger without a knob has a threaded pin or pull ring. On the other hand, lock and clamp plungers combine clamping functions with the primary indexing function. The retractable nose enables one to fix and release the components with ease. When releasing a component from the plunger’s fixed position, all you need is to pull the device’s handle.

Hand Retractable Spring Plungers

Hand retractable spring plungers are made from stainless steel, brass, or steel to protect against corrosion. These devices have 10-32 or one to eight threads, and a piano or stainless steel wire thread based on type. Hand retractable plungers are useful in most medical, consumer, and industrial applications for positioning, indexing, and fastening devices. They can also be used in sports equipment.

Hand retractable spring plunges allow instant single-hand operations. You only need to twist the handle 90 degrees to lock the plunger in.

Push In Spring Plungers

Push in spring plungers or two-way spring plungers are suitable for positioning, engaging, or clamping various components. These plungers have unique tapped holes on both ends to attach knobs, grips, prisms, and other inserts. Most push in spring plungers are made from steel. They also come with fixed-in hexagonal tapped pins for thrusting and tractioning.

Conclusion

This article explains basic information about spring plungers, from the components to uses to types. It ensures you know which type of spring plunger is suitable for what equipment. It’s, therefore, essential to purchase the right spring plunger suitable for your task. For instance, press fit spring plungers are more suitable for soft materials than threaded spring plungers.