Tog-L-Loc

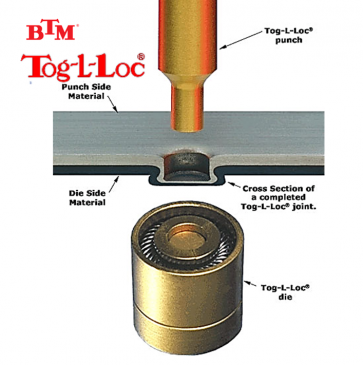

Tog-L-Loc® is a process known as clinching which cold-forms the part metal using a special punch and die to form a strong interlocking clinch joint. The result of the process is a round, button shaped extrusion on the die side of the assembly, and a small cylindrical cavity on the punch side. The clinch joint requires only the sheet metals that were joined. No external fasteners, or welding is utilized in the process.

From simple tooling to high speed automation, BTM can provide solutions to your manufacturing requirements. Fast, economical and consistent, Tog-L-Loc is used worldwide in the automotive industry and in the manufacture of domestic appliances and other products formed from sheet plate.

Tog-L-Loc® Features & Benefits

- Steel metal joining made easy.

- Joins plain, coated, and dissimilar metals - without burning the coating.

- A clinching process - No rivets, screws, or other fasteners are used.

- Eliminates spot welding operations.

- Long tool life: 300,000 joints common.

- Joints are created in a single press stroke.

- Non-Destructive testing with a simple gauge.

- Strong, leak-proof joints are highly fatigue resistant.

- Environmentally Friendly process - Creates no sparks, fumes, or soot.

Increase QUALITY

Increase PRODUCTIVITY

Increase PROFITS

REDUCE Down Time

REDUCE Scrap Rates

REDUCE Costs

| Weight | 0.0100 |

|---|---|

| Material | 0 |

| Standard Number | No |

| Second Standard | No |

| Drive | 0 |

| Head | - |

| American Generic Brand Term | No |

| Diameter | 0 |

| Length | No |